Compactors

New

2020 Wacker Neuson DPU110rLEM970

In Stock

Call for pricing

Description

The DPU110r infrared remote controlled reversible vibratory plate offers maximum power, performance and ease of use. The innovative exciter control enables to the plate to be steered with pin-point accuracy with not loss of performance. The infrared control system maintains line-of-sight operation protecting the operator from vibration, emission and noise. Designed for the compaction of granular and mixed soils, the DPU110r offers over 24,000 pounds of centrifugal force to handle the toughest compaction jobs.

Features

- Powerful centrifugal force, fast travel speed and high frequency rate in a rugged design

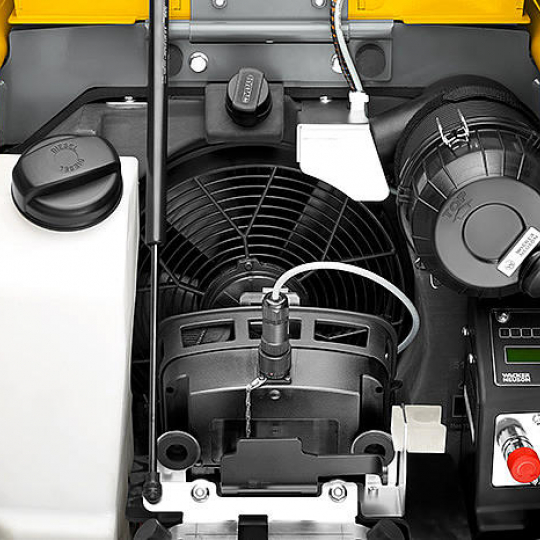

- Designed for optimum serviceability, making routine maintenance quick and easy

- Intelligent water-cooled engine designed for ambient temperatures up to 122 °F (50 °C)

- Available with either machine protection sensor that detects machine overload or Compatec, compaction detection system with overload protection

- First-class compaction performance

- Individually controllable compaction performance, optimized adaptation to the soil being compacted

- Water-cooled engine, optimized for the plate’s requirements

- Stable base plate: very good rate of advance for fast compaction and optimum results

- Remote Control for great user comfort

- Precise and continuously variable control in curves

- The remote control can be recharged under the plate’s lockable hood. This also provides protection against theft.

- The simultaneous operation of several remote controlled vibratory plates is easily possible

- Intuitive controls, no training necessary

- Very safe: The remote control only works when in direct visual contact with the plate

- Optimum protection: The infrared sensor gives way when being pushed

- The proximity recognition protects the operator from losing control

- Ecological & sustainable

- The water-cooled engine meets all emission regulations future-proof and allows operation at extreme temperatures

- Water-cooling provides extremely long engine service life even with long-term operations

- Way below the noise exposure limits - that protects the environment and operator

- Extremely robust design

- The steel tube frame and steel cover sheets make the DPU110r very robust and protected against damage

- The side panels are detachable

- Durable and very stable design

- Safety

- Tie-down options similar to those of large equipment allow an optimal securing during transport

- The lifting eye is turned by 90 degrees and thus provides better protection of hood and center pole when being lifted.

- Center pole and control elements cannot collide with the excavator arm when being transported.

- Maintenance and Service

- 100% service access with a few easy steps

- Detachable side panels

- Hood can be fully opened

- Long service intervals due to large air filter

- Easy to clean base design without the risk of damaging hydraulic hoses

- Intelligent equipment protection

- Black box allows communication between man and machine

- Operating displays provide information on overload protection and error logs

- Individual configurations possible

- Theft protection via PIN set

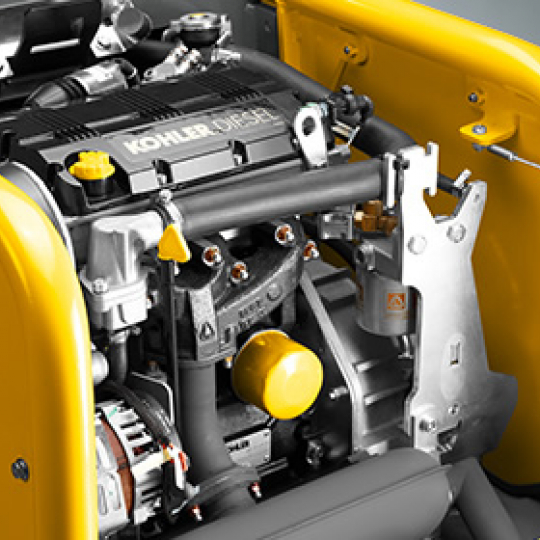

- Reversible Vibratory Plate with remote control, with water-cooled Kohler diesel engine, e-starter, machine overload protection, operating width 38 inch (970 mm)

Specifications

Engine

| Engine / Motor Manufacturer | Kohler |

| Engine / Motor Type | Water-cooled 3-cylinder 4-stroke diesel engine |

| at rpm | 2,700 rpm |

| Displacement | 1,028 cm³ |

| Fuel tank capacity | 11.2 l |

| Engine / Motor | KDW1003 |

| Fuel type | Diesel |

| Fuel consumption | 3.3 l/h |

| Power transmission | Hydrostatic |

| Permissible tilt | 25 ° |

| Engine performance (rated power) (DIN ISO 3046 IFN) | 16 kW |

| Operating performance (DIN ISO 3046 IFN) | 12 kW |

Operational

| Frequency | 60 Hz |

| Centrifugal force | 110 kN |

| Advance travel max. (dependent on soil and environmental influences) | 28 m/min |

| Surface capacity max. (dependent on soil and environmental influences) | 1,630 m²/h |

Dimensions

| Transport length | 1,515 mm |

| Base plate thickness | 14 mm |

| Operating width | 970 mm |

| Transport height | 1,000 mm |

| Transport width | 1,050 mm |

| Base plate length | 1,183 mm |

| Base plate width | 970 mm |

| Height (ground clearance) | 830 mm |

Weights

| Operating weight | 810 kg |

| Shipping Weight | 853 kg |

Canadian Owned, Alberta Strong

SSR Equipment Ltd is your one stop compact equipment dealership.